Design & Engineering

We take full ownership of the project delivery process, ensuring successful outcomes at every phase.

Structural engineering

Structural engineering forms the foundation for all structures we design. Designing for offshore environments requires advanced modeling and analysis in compliance with the latest codes and standards. Our designs are reinforced by cutting-edge 3D modeling, utilising the most up-to-date software tools such as AutoCAD, Navisworks Manage, Advanced Steel, Tekla, RFEM, SACS, Femap and Ansys.

Our engineers ensure that every designed structure is resilient, capable of withstanding harsh environmental elements such as wind, water, and seismic activity in earthquake-prone areas.

Mechanical engineering

Our mechanical engineers design smart installation tools such as lifting equipment, heave-compensated gangways, piling equipment, cable lay equipment and cable carousels. The advanced tools we utilise for mechanical engineering include: AutoCAD, Navisworks Manage, Solidworks, Inventor, Tekla, RFEM, Femap and Ansys.

Process engineering

Enersea’s process engineering team provides analysis and design of processing systems for the hydrogen, hydrocarbons and CCUS markets. We provide steady state and transient simulations for simple and complex systems which set the base for other disciplines such as Piping and Electrical, Instrumentation & Control. We use simulation software such as: AutoCAD, HYSYS Suite, Unisim, PipeSim and OLGA.

E, I & C

Our Electrical, Instrumentation & Controls team conducts extensive grid studies, along with dynamic and transient analyses within the time domain, ensuring reliable and efficient system performance. We also specialize in the seamless integration of process and electrical control designs, with a primary focus on FEED and Detailed Design, where integration is most critical. Our simulation software includes: AutoCAD, Navisworks Manage, Power Factory and PSCAD.

Piping

At Enersea, we specialise in the design and engineering of piping systems, including tanks and compressors, for hydrogen and hydrocarbon offshore platforms. Our piping engineers collaborate closely with the process team to develop optimised platform layouts. Once the process design is defined, we execute the piping design for fabrication, ensuring seamless integration with equipment and structural elements. Our piping engineers use the following software tools: AutoCAD, Autodesk Plant 3D, Navisworks Manage and Autopipe/CAESAR II.

Pipelines & subsea

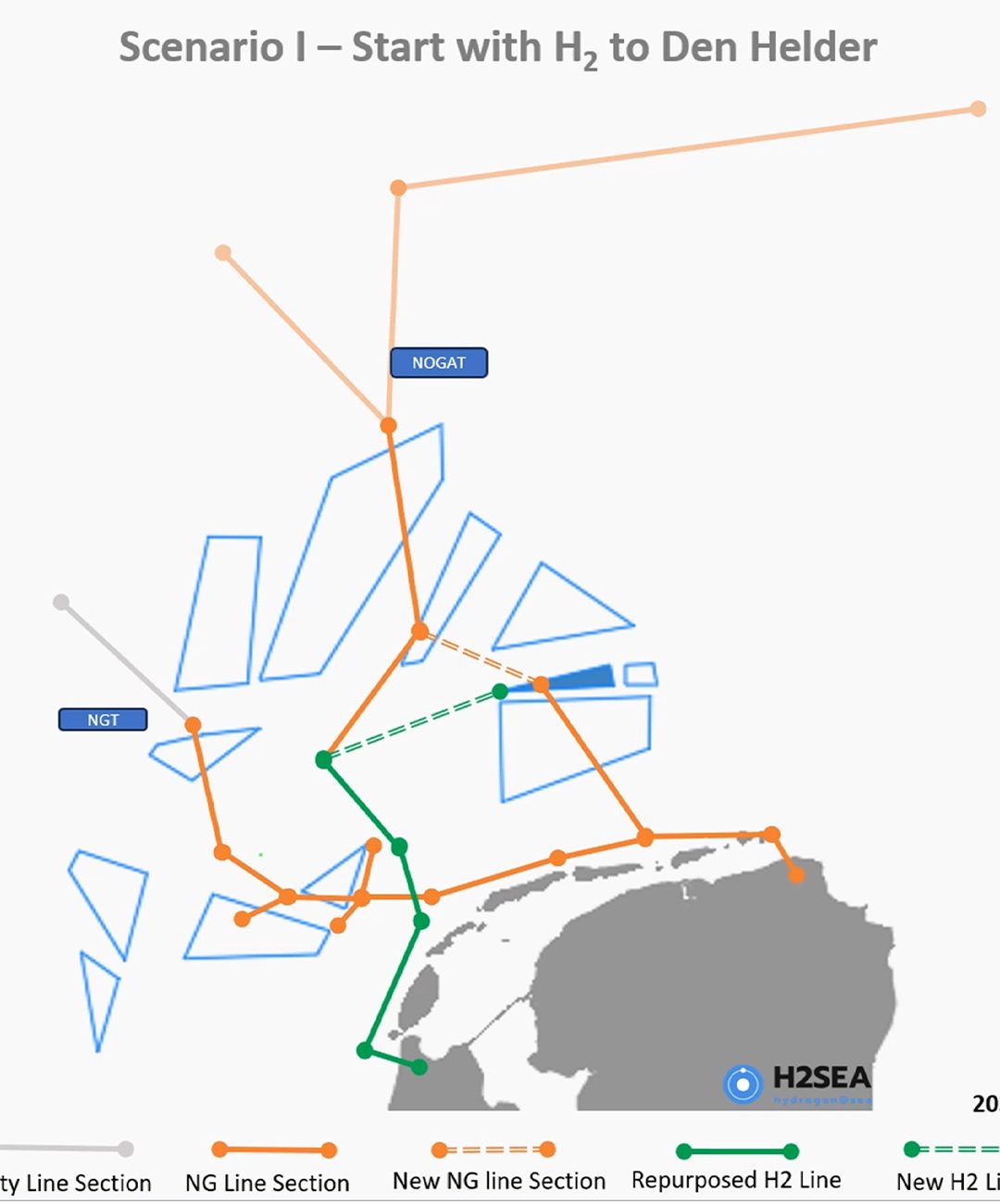

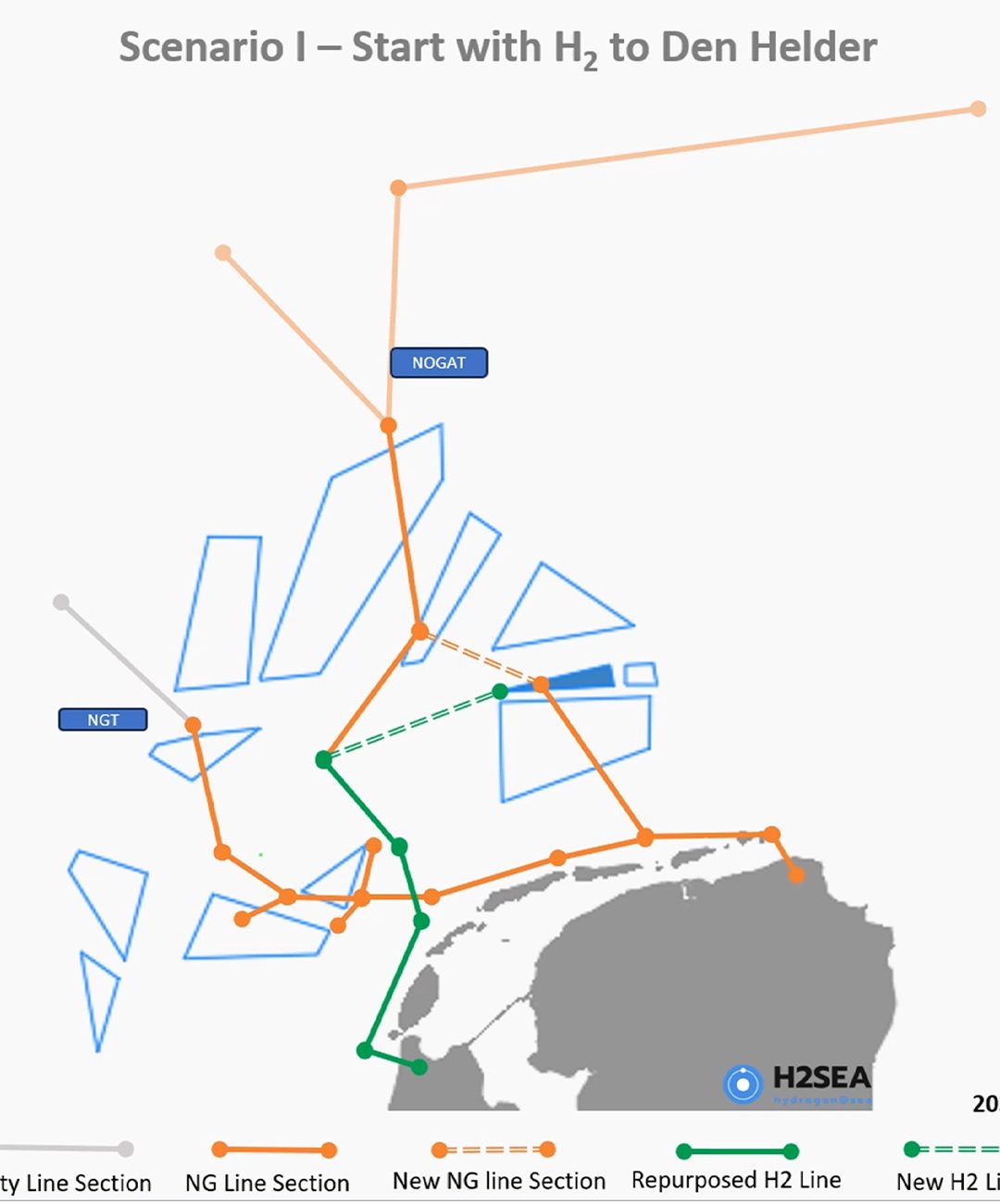

Enersea’s pipeline design approach covers both concept and detailed design, with a strong emphasis on pipeline integrity. We also specialise in flow assurance, installation management, lifetime extension, and repurposing existing hydrocarbon pipelines for new applications such as hydrogen transport or CCUS. Our subsea engineers are experts in the design of underwater structures and connections. From securing jackets to the seabed, to integrating risers and spools into platforms, as well as executing underwater pipeline connections and hot taps. Our pipeline & subsea team delivers solutions for complex subsea challenges. The tools they use include: AutoCAD (Civil), Navisworks Manage, Ansys, Autopipe and in-house tools.

System engineering

At Enersea, our system engineering services ensure seamless integration across all engineering disciplines. We take a holistic approach to system design, prioritising functionality, performance, and reliability, always with our customer’s interest in mind. From requirements analysis to verification and validation, we provide smart solutions tailored to the specific needs of offshore projects, ensuring optimal performance and efficiency.

What our clients say about us

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

Feel free to get in touch!

Looking forward to meeting you.Dieter Korndorffer - Managing Consultant

- Phone: +31 (0)10 31 32 100

- E-mail: info@enersea.nl