Consultancy

Decision support integrating technical & economic aspects

Enersea provides decision support by integrating technical insights and economic considerations. We utilise our in-house developed decision model, incorporating CAPEX, OPEX, and tariff evaluations, recognising that project value and success are determined in the initial phase. With extensive experience in engineering project management and risk awareness, Enersea delivers critical value during these early stages.

Design reviews & due diligence

A key aspect of our consultancy services is conducting technical design reviews and due diligence for existing equipment to ensure suitability for upcoming projects.

These reviews focus on mitigating project risks, providing clients with critical insights to prevent potential future issues. Enersea offers technical due diligence support during acquisitions or asset evaluations, ensuring informed decision-making and reliable outcomes.

R&D for proprietary design

Innovation doesn’t always mean new technology. At Enersea we are very good at turning innovative ideas into practical designs using today’s technology. Often, it’s about finding the best way to combine existing technologies, systems, and methods to meet all requirements effectively.

What our clients say about us

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

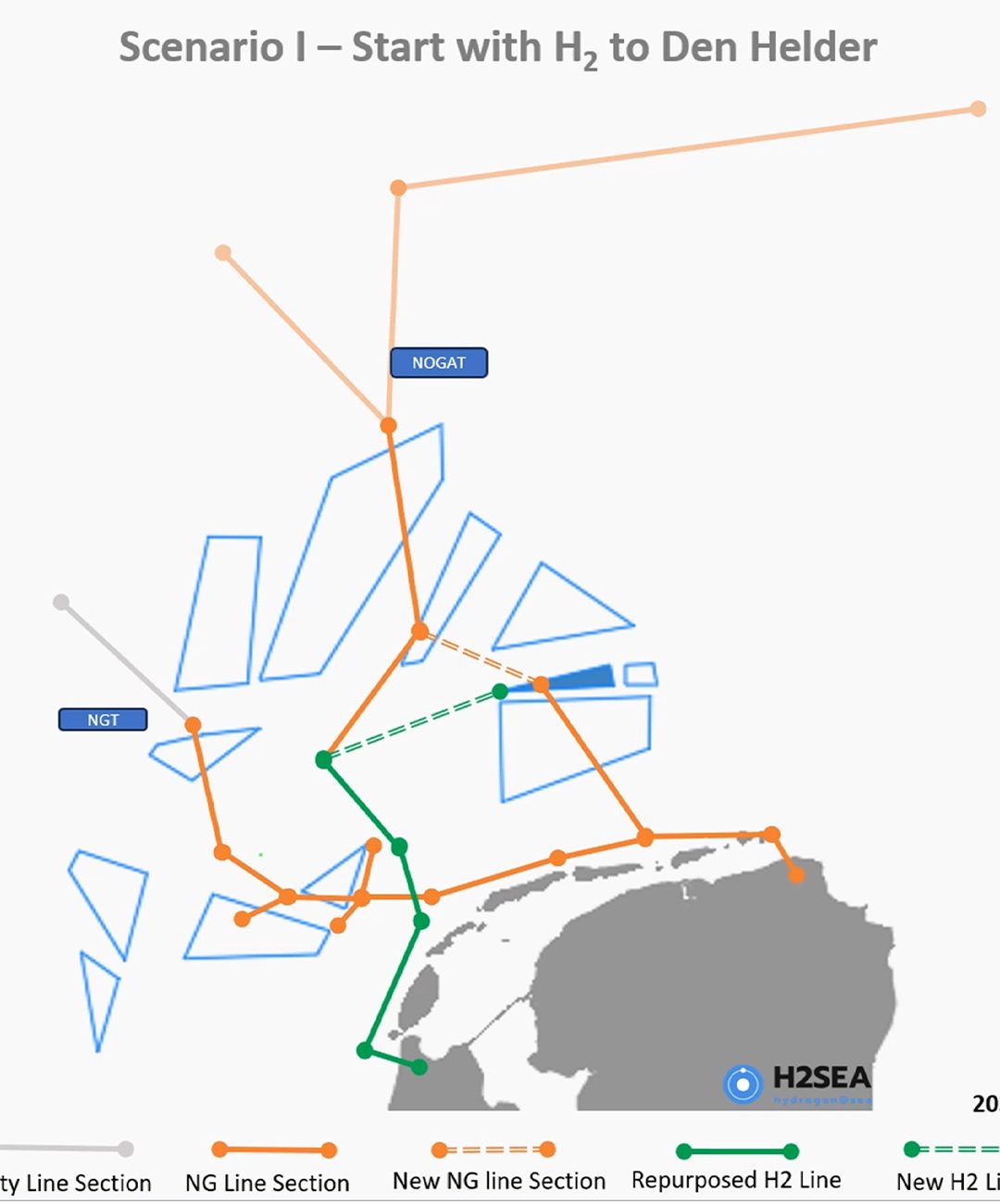

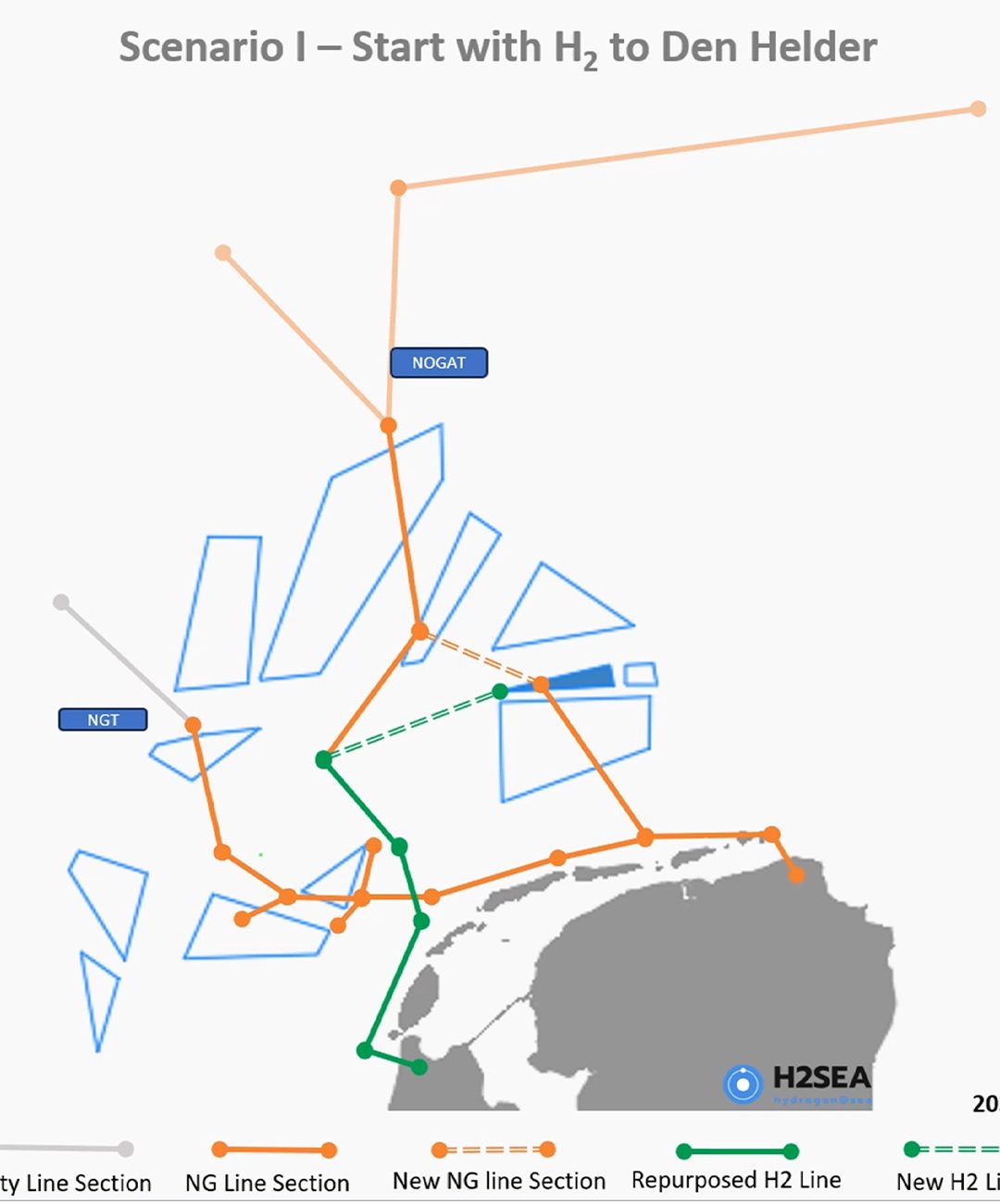

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

Feel free to get in touch!

Looking forward to meeting you.Edwin van Drunen - Managing Consultant

- Phone: +31 (0)10 31 32 100

- E-mail: info@enersea.nl