Stage 2+ Project – A15 & B10 Development for Petrogas

Client: Petrogas Transportation B.V.

Location: Northern Sector of the Dutch North Sea

Project overview

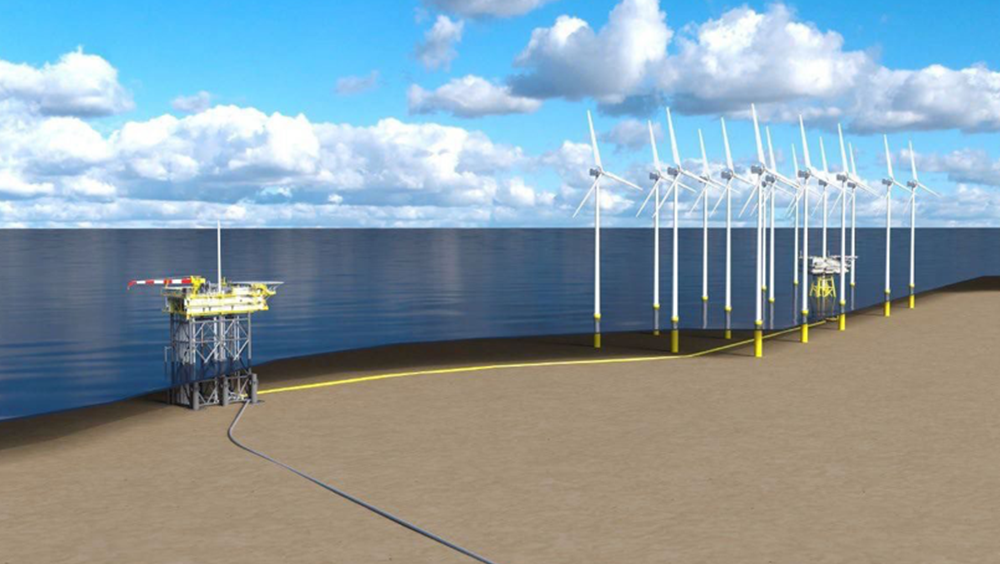

The Dutch offshore A/B Blocks are located some 300 km offshore north of Den Helder and contain considerable volumes of low pressure, nearly pure methane at shallow depths.

The A/B Shallow Gas Development is, unlike any other Dutch offshore development, requiring compression from start-up in order to export the gas to shore. A sequential area development of the A/B Blocks gas accumulations was planned. The staged approach for the development initially (Stage 1) focused on the larger fields A12, B13 and A18 field. These fields have been developed and the second stage of the development focusses on the smaller fields within the area, i.e. A15, B10, B16 and potentially some new discoveries. This part of the development is called Stage 2+.

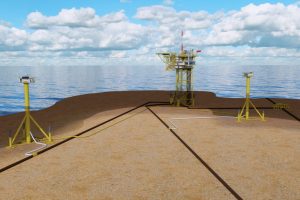

A/B Shallow Gas Development

The A15 development includes the design of a new unmanned minimum facility platform producing wet gas into the existing A18-A12-CPP pipeline, located close to the eastern side of the platform location. An umbilical will be directly tied back from A15 to A12-CPP to provide controls and power.

The B10 development includes an identical design as per A15 producing wet gas into the existing B10-A12-CPP pipeline, located at approximately 6.7 km of the platform location. An umbilical will be directly tied back from B10 to A12-CPP to provide controls and power.

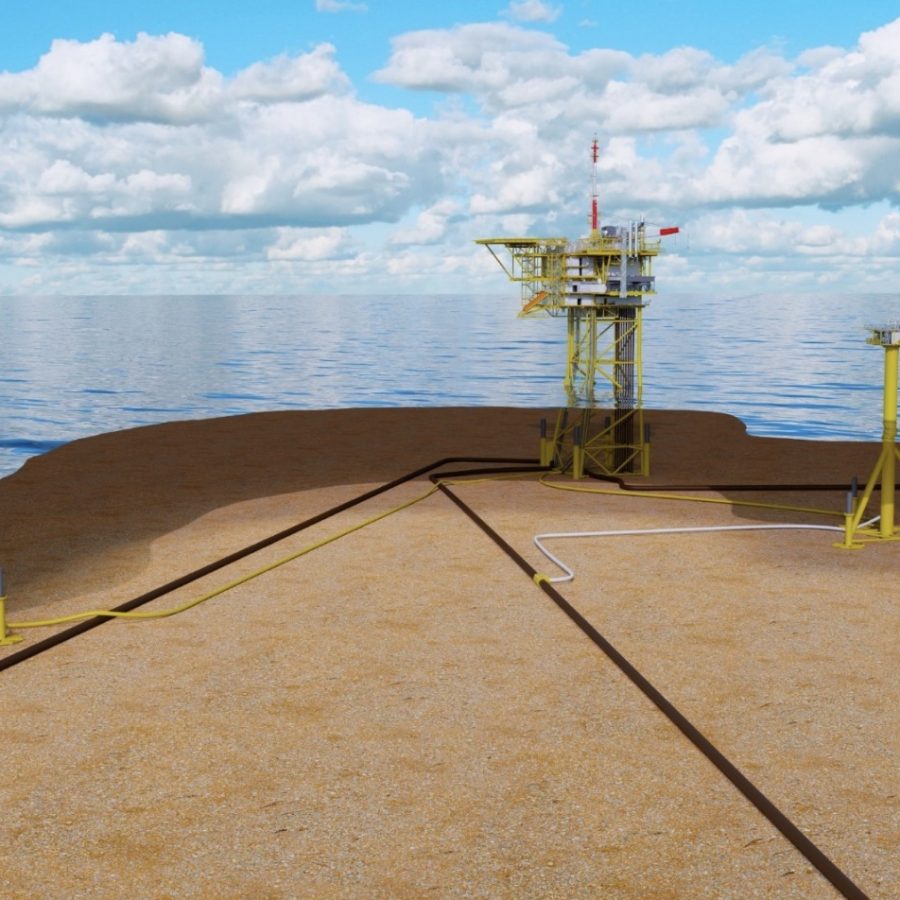

A12-CPP is the central processing platform where gas and liquid are separated. The gas is compressed in a booster compressor and an export compressor to meet the required export pressure. The gas is dehydrated to the required export specification prior to exporting the gas via a 16” pipeline into the NOGAT pipeline. B13 and A18 are existing satellite platforms that produce to A12-CPP.

Considering the tie-back to existing pipelines, which are both in service, a hot tap tie-in shall be installed. Doing so a full de-pressurization and flooding of the pipe will be avoided and production of A18 or B13 will not be compromised.

Both umbilicals for A15 and B10 are identical in functionality and cross-section. The tie back to A12-CPP will take place by installing two additional J-tubes on one of the existing platform jacket leg.

The resulting field lay-out after Stage 2+ is as outlines in the figure below.

Concept Design

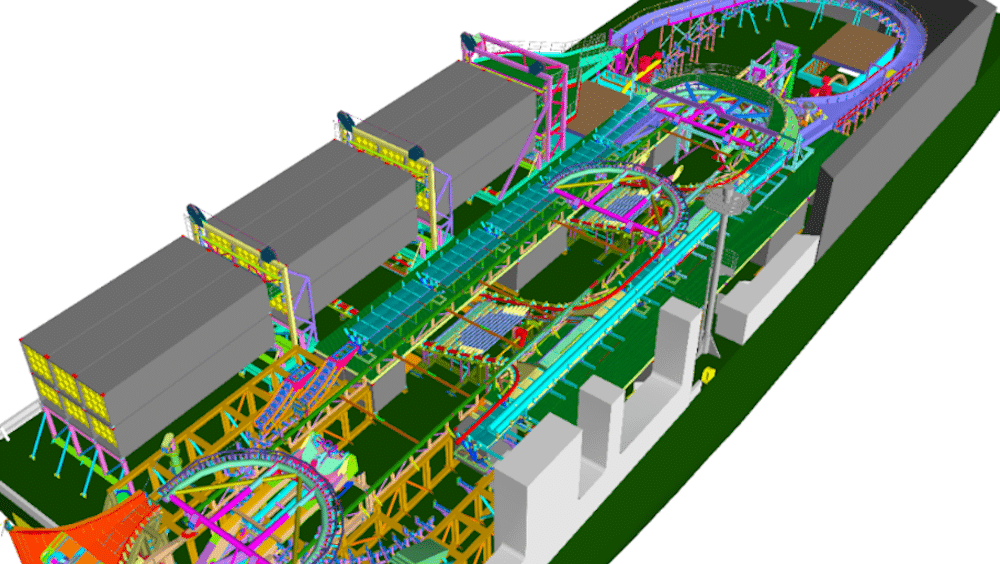

Creating a platform datasheet outlining the design parameters for the A15 and B10 development.

Full FEED Design

eveloping the complete basic design for the A15 and B10 gas fields, including platform design, pipeline infrastructure, and subsea systems.

Detailed Design: Completing the full detailed design ensuring engineering solutions were fully developed and ready for execution. As part of the detailed design, Enersea also provided engineering support during the fabrication phase of both platforms.

Hot Tap Installation

Designing the installation of a hot tap, which allows for the connection of the new fields to the existing A12 pipeline while maintaining uninterrupted production.

Brownfield Modifications

Performing necessary brownfield modifications on the A12CPP platform to accommodate the integration of the new fields. In broad terms this includes installing power cables from the Uninterruptable Power Supply (UPS), control cables to the Distributed Control System and Emergency Shutdown system (DCS and ESD), a Topside Umbilical Termination Unit (TUTU), a Hydraulic Power Unit (HPU) and a connection to the Methanol package.

Subsea Scope

Responsible for the design and engineering of subsea infrastructure, including the design of two control umbilicals to link the A15 and B10 fields with the A12-CPP host platform.

Foundation Engineering

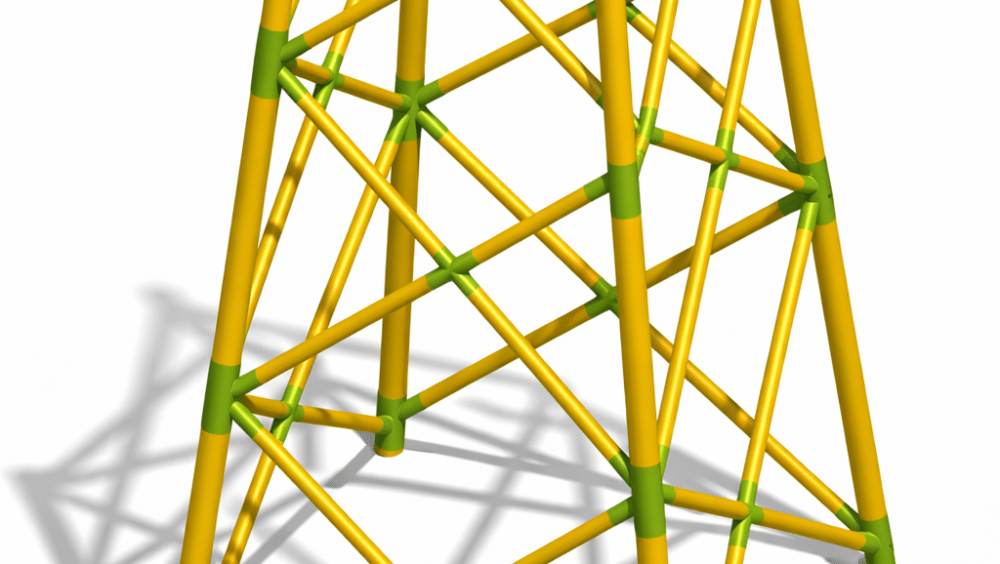

In collaboration with Cathie Associates, providing soil calculations for the platform foundations, ensuring structural stability.

Technical Safety Analysis

Working with Versatec (FEED) and Treecon (Detailed Design) to carry out a comprehensive technical safety analysis for the project, ensuring safe operation during and after the installation.

Feel free to get in touch!

Looking forward to meeting you.Dieter Korndorffer - Managing Consultant Hydrocarbons

- Phone: +31 (0)10 31 32 100

- E-mail: hydrocarbons@enersea.nl