Reusable Monopile Cover for Vattenfall

Client: Vattenfall

Location: Hollandse Kust Zuid (HKZ) offshore wind farm, North Sea

Project overview

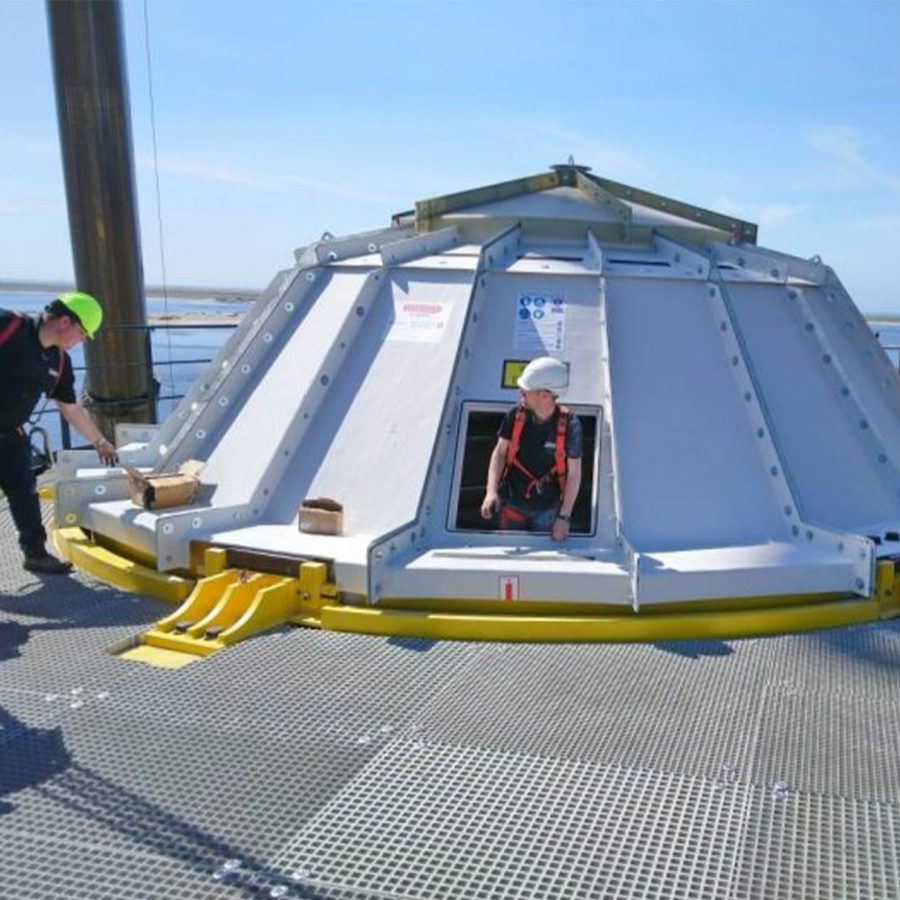

For Vattenfall’s Hollandse Kust Zuid (HKZ) offshore wind farm, Enersea developed an innovative, reusable monopile cover in collaboration with polyester manufacturer Theuws, with support from the Stimulus Programme ‘Kansen Voor West’. Unlike traditional aluminum or steel covers, which are energy-intensive to recycle and not reusable, the new cover is made of fiber-reinforced polyester panels, designed to be durable and adaptable to various monopile diameters, ranging from 6 to 8 meters.

Project Significance

The reusable monopile cover reduces material waste and energy consumption in offshore wind operations, offering an eco-friendly alternative to conventional monopile covers.

Already during the course of this project, Theuws and other parties involved founded a separate company named CCM: Composite Cover Manufacturing, dedicating it exclusively to the development, production and even leasing of reusable monopile covers. Enersea is proud to still being involved as the engineering party.

Concept and Detailed Design

In co-operation with Theuws, Enersea created a sustainable cover design that resembles interlocking “pie slice” panels, allowing adaptability and reusability across different monopile diameters.

Finite Element Analyses

Enersea collaborated closely with engineering firm FEMTO to conduct Finite Element Analyses (FEA) on the composite materials. This partnership ensured rigorous strength calculations, validating the design’s structural integrity and resilience under operational conditions.

Prototype Development and Testing

Enersea worked closely with Theuws and FEMTO to complete the detailed design and produce the first prototype. Testing conducted at Theuws' yard and Sif’s terminal validated the design’s functionality, load resistance, and water tightness.

Feel free to get in touch!

Looking forward to meeting you.Dirk Pulles - Managing Consultant Offshore Wind

- Phone: +31 (0)10 31 32 100

- E-mail: wind@enersea.nl