Fabrication support for Tideway's Living Stone cable lay system

Client: DEME

Location: International Waters

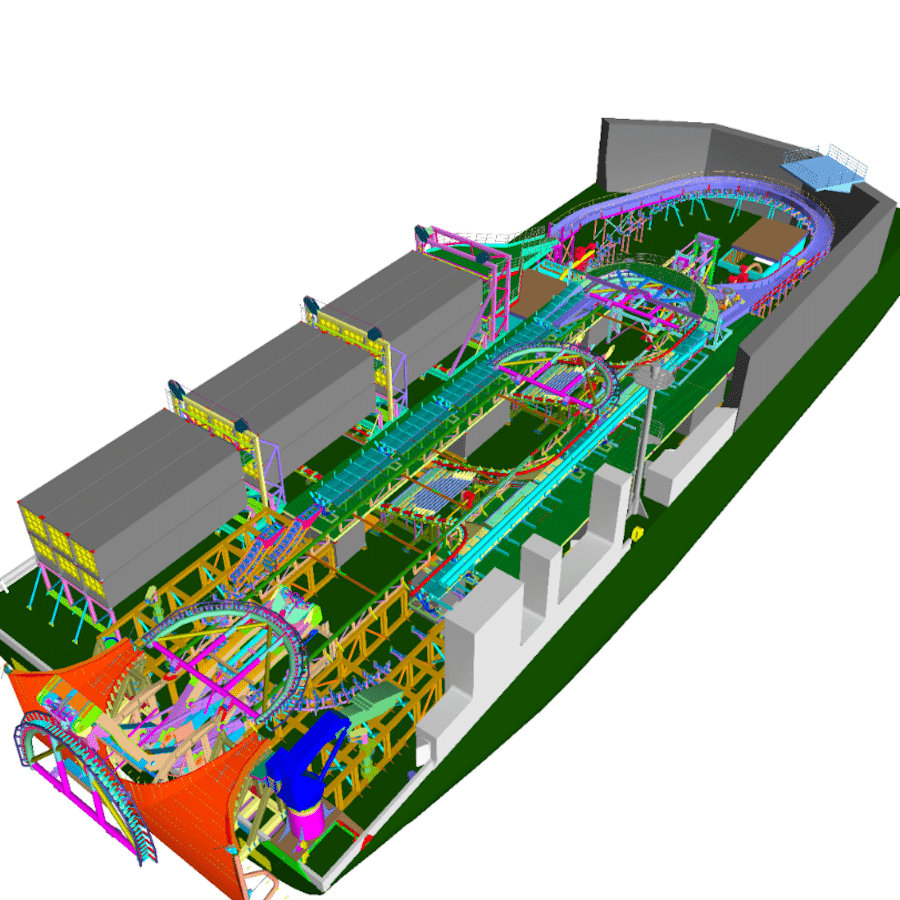

An engineering team of Enersea is rendering fabrication support during the manufacturing of the cable lay street of Tideway’s new built vessel Living Stone.

Previously Enersea took care of the concept, basic and detailed mechanical design of the vessel’s deck lay-out and equipment. Enersea also specified the control, hydraulic and electric systems and even assisted in the tendering process.

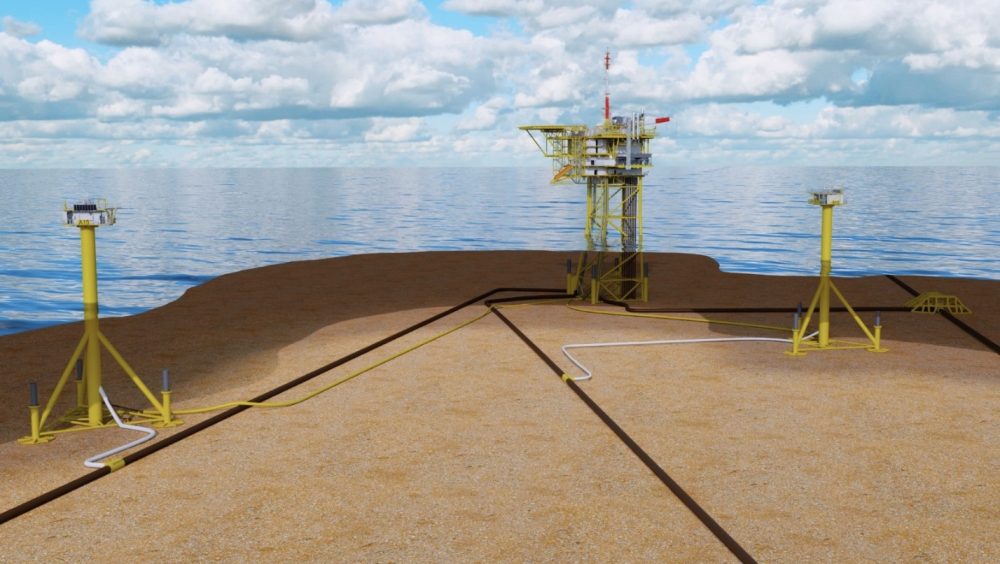

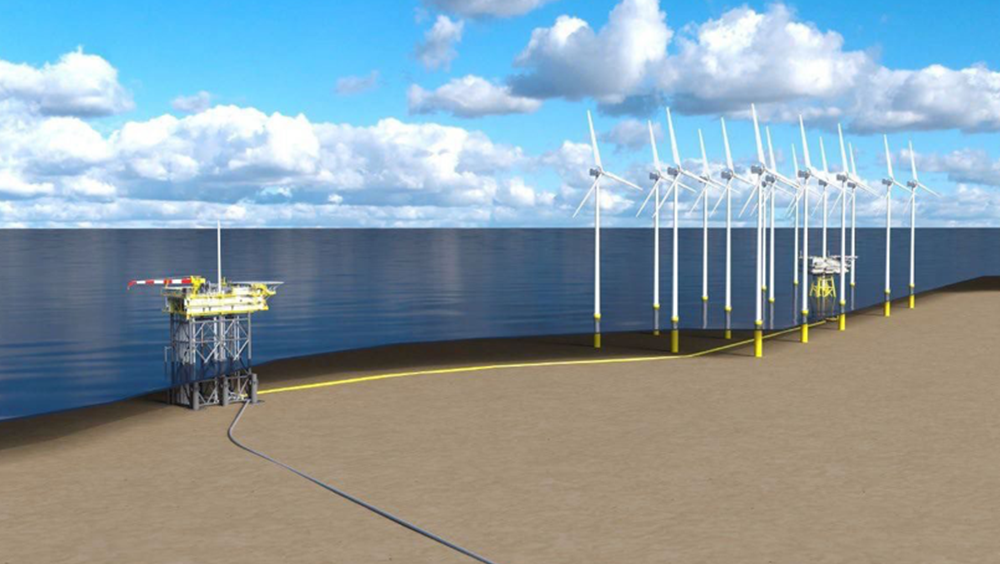

One of the design criteria demanded that the configuration of the vessel could be quickly changed from cable laying into precision rock placement. With the modular design of the cable installation system, this is possible within days. Different configurations, with short turn-around times, are possible depending on the cable requirements. The cable lay system can also be easily transferred to a different vessel.

Special about the Living Stone is that the two 5000 tonnes cable/umbilical turntables are stationed below deck, leaving a 3500m2 free deck that can accommodate different cable lay configurations. Apart from the cable lay street, the deck can accommodate a fall pipe system, ROV’s, subsea trenching tools and a 700 tonnes crane. The vessel is also fitted with a 7.7 by 7.7m moonpool. The design of the cable lay system has been focussed around cable and CPS logistics, making the Living Stone unrivalled in the current market with regard to cable installation efficiency.

On the quay-side of the brand new Reimerswaal ship yard in Vlissingen, Tideway will first test the complete cable lay street before it will be installed in modular sections on board the Living Stone. During the complete project, Enersea engineers have been an integral part of the Tideway project team and as such all engineering knowledge is also present during the fabrication and mobilisation phase of the deck equipment.

Feel free to get in touch!

Looking forward to meeting you.Kasper Koch - Technical Consultant Mission Equipment

- Phone: +31 (0)10 31 32 100

- E-mail: equipment@enersea.nl