Markets

Enersea operates across four key markets: Offshore Wind, Mission Equipment, Hydrogen and Hydrocarbons.

We are Enersea

Our team combines deep offshore engineering expertise with extensive experience to deliver exceptional results. We are committed to providing integrated technical solutions that optimise investments and maximize value for our clients. Our people are at the core of our success; innovative, skilled problem solvers ready to tackle your offshore challenges.

What our clients say about us

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

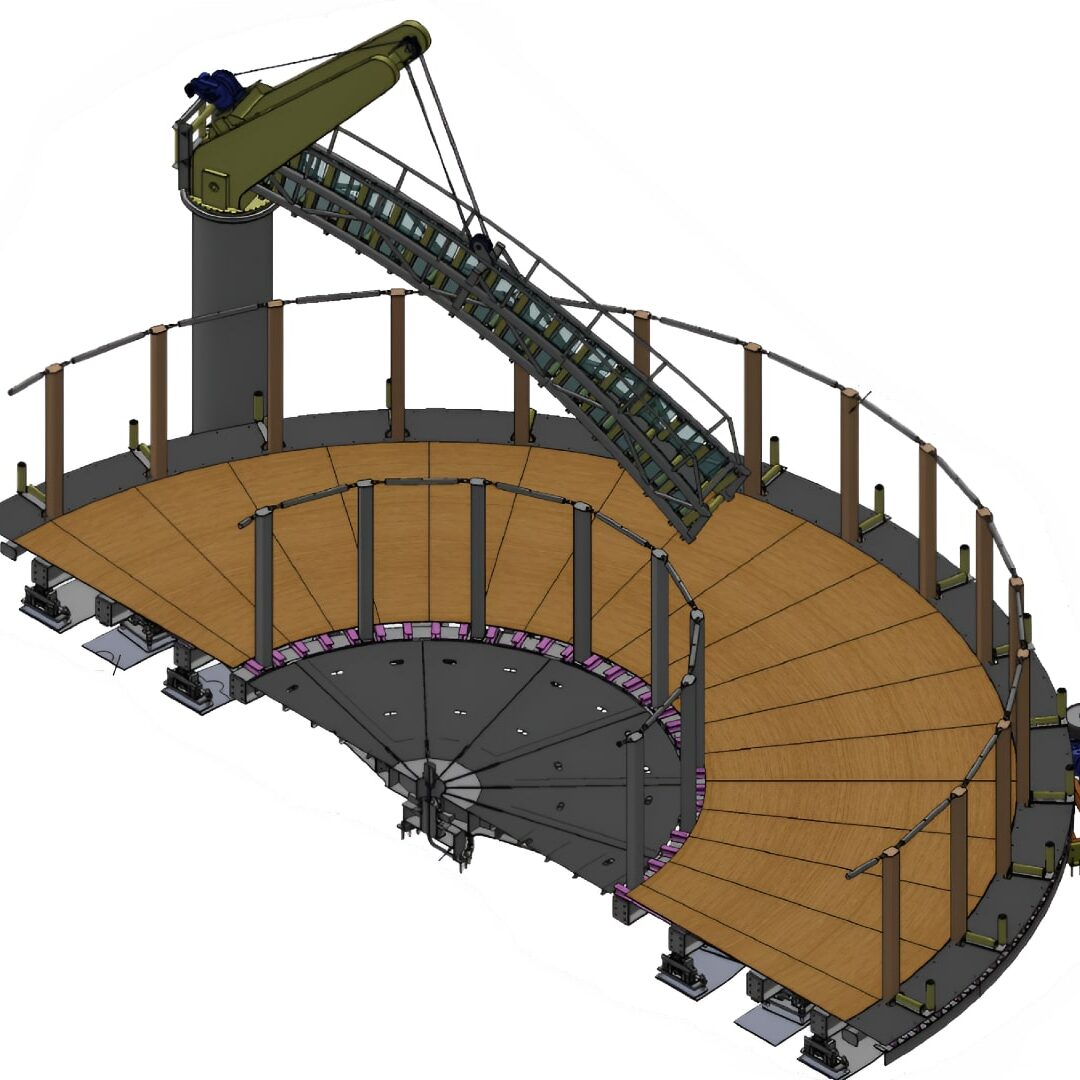

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

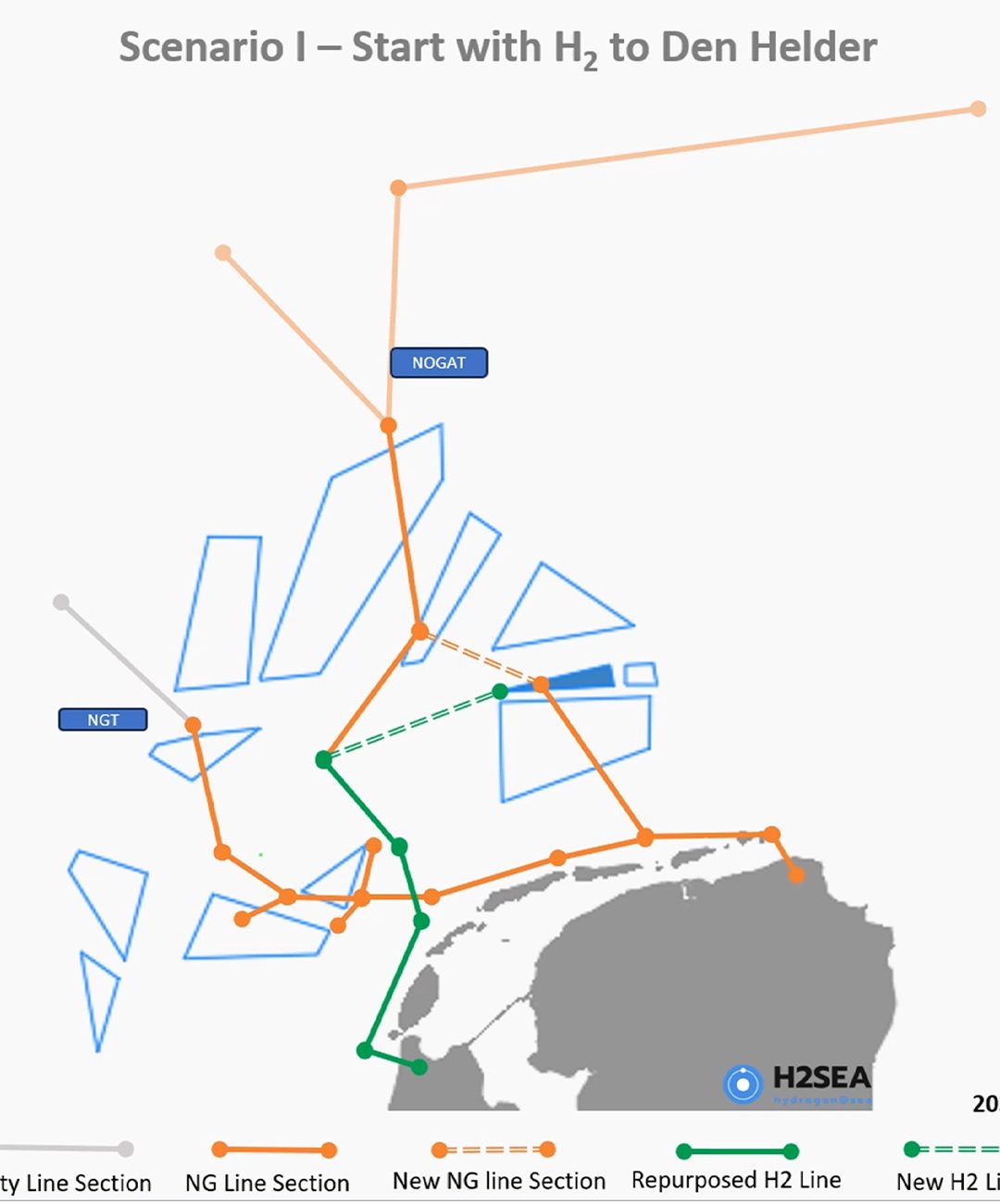

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

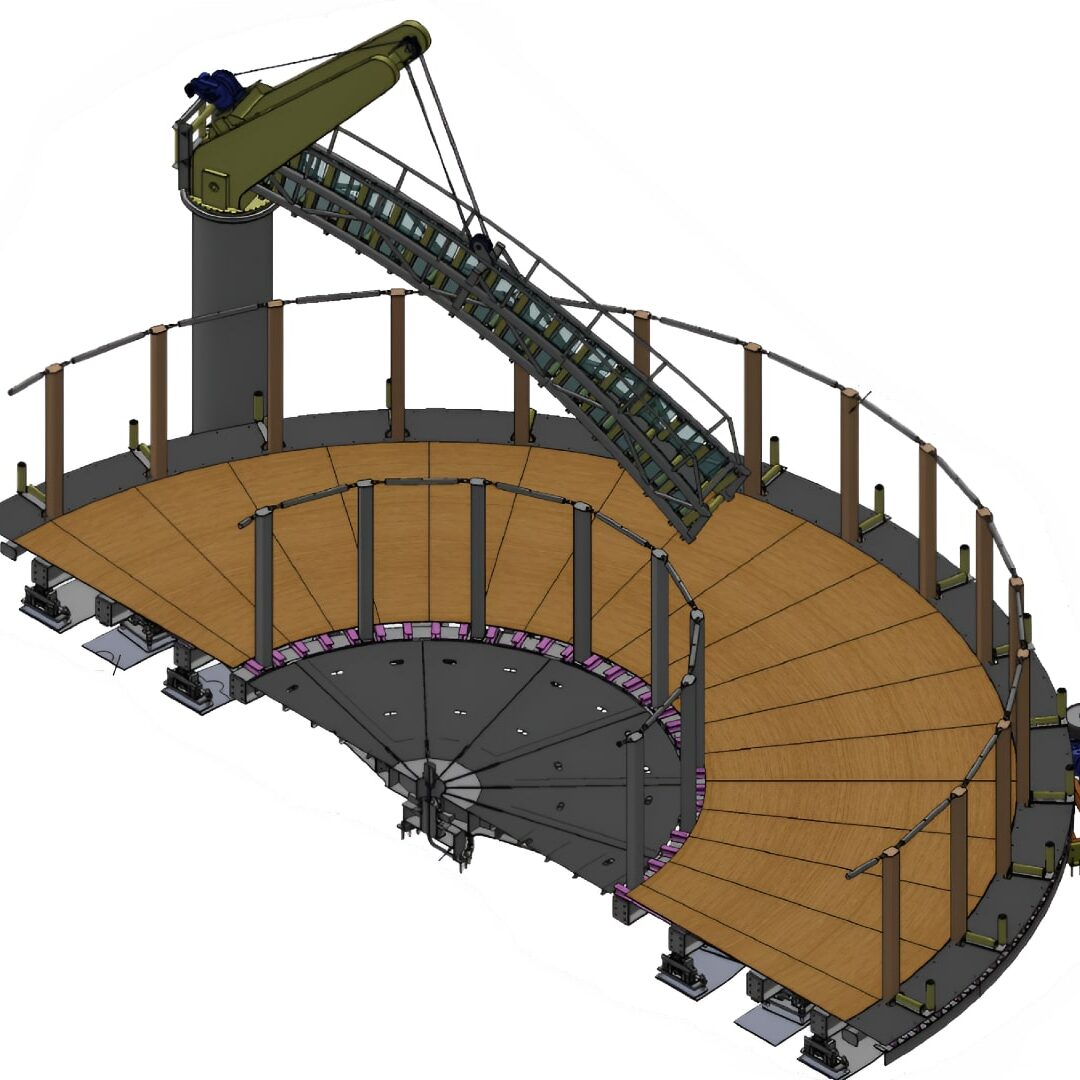

Enersea designs cable carousels for us; suitable for vessels and factories. With expertise that extends to solutions for even seismic-prone areas, they integrate seamlessly with our organisation, acting as a natural extension of our team. We look forward to more successful projects together.

TouchWind is proud to collaborate with Enersea, who provides us with expert engineering and onsite support for the development of our tilting angled one-piece rotor floating wind turbine. With their expertise, we are on track to deliver the world’s first low-cost floating wind turbine.

In less than a year, Enersea completed the concept & detailed design, provided fabrication and onsite support for Viking Neptune’s cable installation system. An impressive achievement, as such projects typically take three years. The result was a cutting-edge system ready for operation.

Enersea conducted excellent strategic and engineering studies on repurposing offshore gas infrastructure for hydrogen transport. Their assessment of production phasing, flow assurance, and fatigue loading confirmed the system’s long-term suitability, giving us confidence to enable hydrogen transport by 2030.

Enersea’s expertise in small, economically challenging fields, persuaded Petrogas to choose Enersea and HSM for an EPC contract on the A15 and B10 platforms. Their detailed design of minimal facilities platforms and tripod foundations ensured seamless fabrication, installation, and commissioning without issues.

Enersea designs cable carousels for us; suitable for vessels and factories. With expertise that extends to solutions for even seismic-prone areas, they integrate seamlessly with our organisation, acting as a natural extension of our team. We look forward to more successful projects together.

Feel free to get in touch!

Looking forward to meeting you.Pascal Ferier - Managing Consultant CEO

- Phone: +31 (0)10 31 32 100

- E-mail: info@enersea.nl